Pure Water

Pure water is required for many applications such as boiler feed water to drum boilers in power plants, pharmaceutical production, semi-conductor manufacturing and the food and beverage industry. For all of these applications reverse osmosis or evaporation /distillation type technologies are required to provide pure water. However, these technologies are susceptible to fouling from the water to be treated if the water has colloidal solids, dissolved (emulsified) oil and metal parameters such as reactive silica. In addition, such parameters as aluminum, barium, iron and zinc can create fouling issues. The RO feed water has to be pretreated, otherwise there will be premature fouling of the RO membrnaes.

RSL Membranes™ are an excellent method to pretreat water for this application. Not only do they provide high colloidal solid and emulsified oil separation but the added benefit of the RSL Membranes™ is their ability to absorb certain metals during the filtration process. Testing and ICP analysis has provided a data base which confirms that RSL Powder™, used as the membrane skin layer, has consistently adsorbed

- Aluminum >85%

- Barium >70%

- Boron >40%

- Fe >85%

- Si >65%

Other metals, to a lesser extent are also being adsorbed.

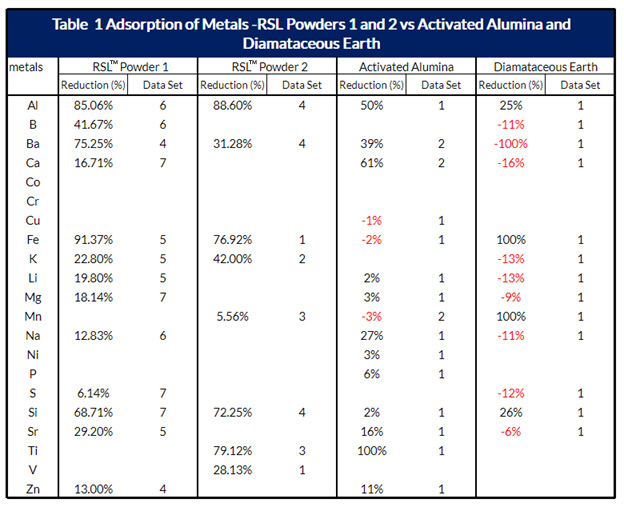

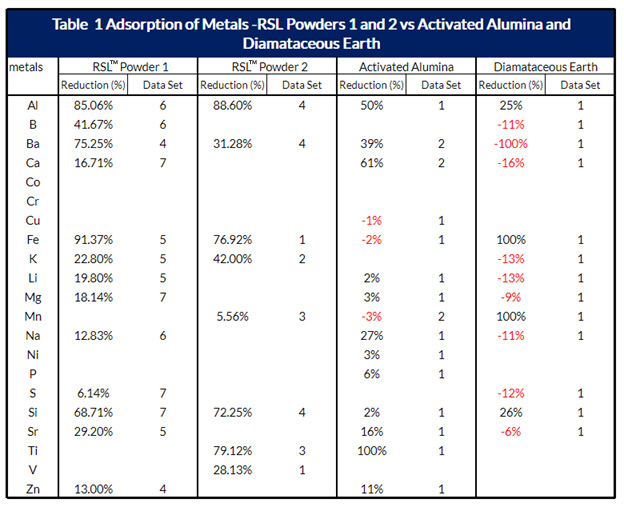

Table 1 summarizes a study that evaluated the adsorption capability of RSL™ Powders compared to conventional media (Activated Alumina and Diatomaceous Earth- DE) used for filter cake/dynamic membrane filtration processes. With this level of adsorption capability, specifically for barium and silica, RSL Membranes™ are an excellent choice for pretreatment of water prior to RO membranes or evaporator /distillation processes in pure water applications. Barium and silica create scaling issues for RO Membranes and evaporators.

Because RSL Membranes™ can handle a high suspended solid load (as high as 5000 ppm), the technology replaces conventional clarifiers or DAF’s. If softening of the water is required through the use of lime or NaOH addition, calcium and magnesium can be precipitated and removed via the RSL Membrane™. Furthermore, the RSL Membranes™ have been used extensively to remove high amounts of silica with the addition of poly aluminum chloride (PACl) to cause a crystallization of the silica.